The world's largest, heaviest

grab dredging system

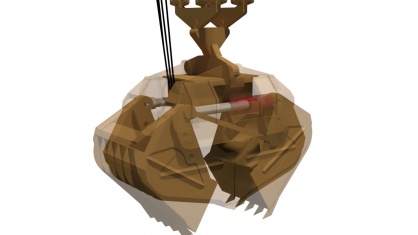

GOSHO's grab buckets have an electric hydraulic system in the bucket frame itself.

This dredger system is totally different from the cutter suction dredger (CSD) and has strong grabbing power due to the grab weight & hydraulic cylinders.

It can dredge not only clay and sand but also hard materials such as SPT100~300 (Soft and medium rock)

Automatically horizontal dredging system is installed, realizing high accuracy & high-efficiency dredging. (Patented)

High energy efficiency with a counterweight grab hoisting system

A balance equation grab hoisting system is adopted.

For this system, the counterweight and grab bucket are connected with 16 wire ropes (φ60mm).

The vertical hydraulic cylinder moves the counterweight to hoist up/down the grab bucket.

The counterweight and the grab bucket are almost balanced.

Therefore, it needs only the power for grasped material during hoisting the grab bucket up.

According to our survey, only 60% of energy is necessary compared to the conventional grab dredger that winch has to hoist both the grab bucket and the material's weight. (Patented)

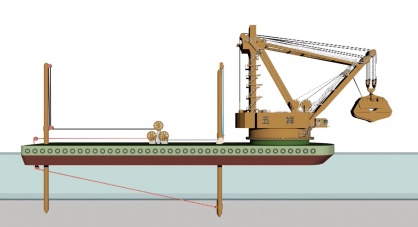

Speedy location adjustment with 2 spuds

GOSHO has two spuds to fix the hull on the sea and move forward after dredging a layer, although general grab dredgers have 3 spuds.

This two-spuds system makes the moving operation speedy, it takes only 3~5 minutes.

This anchorless grab dredger can contribute to a safe & efficient operation even if the site is a congested port.